Cobalt borate came to light through the expansion of inorganic chemistry in the late nineteenth century, right as laboratories started to break ground into the reactions of transition metals with boric compounds. Research communities in Europe began exploring borate systems for their unusual electrochemical properties, finding cobalt particularly attractive for its deep color and potential in energy storage. Early reports linked cobalt borate with synthetic pigments, but its real intrigue rose after the middle of the twentieth century, thanks to work on water oxidation and catalysis. My own introduction to cobalt borate arrived during laboratory rotations, where the mineral keenite often replaced commercial salts to prepare test batches for chemical analysis. The substance left a strong mark on industrial labs searching for nonplatinum catalysts, especially in the rapidly advancing field of renewable energy.

Cobalt borate appears as a blue or violet powder, occasionally crystalline, reflecting the presence of trivalent cobalt ions. A quick scan through any reliable distributor catalog will show the product available for both commercial and laboratory use, with grades ranging from technical purity up to reagent quality. Its value doesn’t just spring from a role as a base chemical—energy storage engineers, battery developers, and coating specialists look to cobalt borate for its stable behavior and ability to promote key reactions. Some suppliers market it as a pigment for ceramics, while others highlight its value in water treatment or as a precursor for advanced battery electrodes.

Cobalt borate forms as a slightly hygroscopic powder with exceptional thermal stability, standing up to temperatures beyond most organic syntheses. Its melting point often lies above 900°C, resisting decomposition until much higher heat. Chemists often appreciate the compound’s remarkable insolubility in water paired with moderate solubility in mineral acids, which stems from the formation of complex ions in solution. Vivid blue and violet hues signal the compound’s d7 electron configuration, a detail that matters greatly in sensor technology and spectroscopic measurements. The chemical combines boron’s lightweight and electron-deficient nature with cobalt’s ferromagnetic and catalytic tendencies—a rare pairing among industrial materials.

Regulatory standards remain key to shipment and handling. Reliable suppliers identify cobalt borate by CAS Number 12046-54-7, commonly stocking the product at purities above 98%. Particle size typically spans between 5 and 40 microns for standard applications, but custom-milled grades support research projects or novel catalyst systems. Labels must carry hazard pictograms—indicating environmental and health risks—alongside GHS signal words and recommendations for personal protective equipment. Laboratories keep cobalt borate in tightly capped plastic jars, protecting both purity and safety.

Industries produce cobalt borate mostly through direct precipitation, dissolving cobalt nitrate or sulfate salts in water and then blending with a borate solution, often sodium tetraborate. The resultant blue precipitate is filtered, washed, and dried under reduced pressure. Some plants opt for solid-state reactions at elevated temperatures to yield more crystalline grades, especially for ceramic or pigment markets. In my experience, adjusting the pH of the reaction often proves decisive—too acidic, and the yield collapses; too alkaline, and the borate phase dominates. Plant technicians spend hours calibrating flow rates and agitation speeds to ensure that the final product emerges free of sodium or sulfate contamination.

Cobalt borate displays a robust chemical profile, readily exchanging ligands or serving as a redox mediator in catalytic cycles. Adding strong acids triggers dissolution and cobalt ion release, supporting a range of analytical and recovery methods. Electrochemical researchers often use cobalt borate thin films as electrodes—oxidation and reduction cycles reshape the material’s surface, boosting its rate performance for oxygen evolution or hydrogen production. Juncture chemists incorporate cobalt borate into complex ceramic matrices by sintering, leveraging its stability and coloration. Vacuum processes and surface treatments allow further modification, opening the door for tuning capacitive behavior or magnetic properties.

Suppliers list cobalt borate under several names, including cobalt(II) borate, boric acid cobalt salt, and cobalt borate hydrate. Scientific references sometimes mention Keenite, a naturally occurring analogue, though commercial batches rarely derive from mineral sources. Product numbers differ between catalogs, but standardized labels ensure safe transport and clear communication in the global chemical trade. During a visit to a pigment supplier, I came across variants with co-dopants like iron or lanthanum, reflecting the ever-present push for specialized formulations.

Cobalt borate, like most cobalt compounds, demands careful management in the workplace. Extended skin exposure or inhalation can cause sensitization, while soluble forms release ions potent enough to disrupt cellular processes. Regulators consider it a suspected carcinogen, listing exposure limits and requiring robust ventilation in processing zones. Direct contact with acids or open flames must be avoided. Spills are dealt with by scooping the dry material into sealed waste containers, and contaminated surfaces require thorough decontamination. At my lab, we always suited up with gloves and particulate masks before handling even small samples, keeping exposure well below guideline values.

Cobalt borate anchors itself firmly in energy technology labs, especially those invested in developing catalysts for water-splitting, fuel cell electrodes, and supercapacitors. Its optical features attract pigment manufacturers and specialty glaze producers, prized in both industrial ceramics and fine art. Analysts deploy cobalt borate in sample preparation, using its oxidation state to quantify and separate metals in complex matrices. Electronics groups seek to harness its semiconducting and magnetic properties for prototype devices, and wastewater engineers explore its action as a coagulant. I once witnessed a team test cobalt borate-doped electrodes for their ability to speed up hydrogen evolution, a project bridging chemical synthesis with sustainable power generation.

University research centers devote significant resources to refining cobalt borate’s properties. Projects span from doping with rare-earth elements for electronic tuning to surface modification for improved electrochemical cycling. Quantum chemists run computational models dissecting electronic structures, seeking ways to push the boundaries of energy conversion. Funding pours into projects aiming to replace natural platinum group metals in electrolyzers, driving process chemists to explore scale-up and recycling routes. Joint ventures between industry and academia crowd scientific conferences, trading results on thin-film deposition, catalyst regeneration, and environmental impact.

Long-term studies suggest cobalt compounds can impact biological systems adversely, especially with chronic exposure. Cobalt ions act at a cellular level, interfering with DNA and enzymatic function. Animal tests show potential for organ toxicity and allergic sensitization, echoing trends among heavy metal borates. Regulatory reviews promote strict workplace hygiene, regular medical screening, and safe disposal protocols. Some groups now look into chelation therapies for accidental ingestion or exposure, and eco-toxicologists monitor the limits for cobalt in surface waters to protect aquatic life. Laboratory routines center on risk minimization, from sample containment to regular air quality checks.

Cobalt borate stands at the intersection of advanced catalysis, renewable energy, and sustainable manufacturing. Interest spikes as industry leaders hunt for alternatives to precious metal catalysts. Scientific groups seek to tailor its structure for next-generation batteries, water-splitting platforms, and thermochromic systems. Increasing emphasis falls on greener synthesis routes, recycling strategies, and circular economy integration. Public and regulatory scrutiny keeps developers on their toes about safety and environmental stewardship, spurring fresh methods for toxicity reduction and selective recovery. As energy storage and clean hydrogen markets expand, cobalt borate’s role looks primed for even broader impact.

Cobalt borate sounds complicated, but it boils down to a hard-working chemical compound fueling progress in chemistry and energy tech. The world pays attention to cobalt because of its battery use, but cobalt borate doesn’t grab headlines. Yet, many researchers know it quietly influences the future of clean energy. Its main job sits in the realm of catalysis, accelerating reactions without burning out. In the big push toward green hydrogen and sustainable energy, scientists lean on cobalt borate to make the oxygen evolution reaction—a key step in splitting water into hydrogen and oxygen—run faster and with less waste. This function matters because splitting water with conventional materials wastes energy and wears out equipment fast.

Chemists often seek materials that endure rough conditions. I’ve watched colleagues wrestle with catalysts that flake apart or gunk up after a few tests. Cobalt borate has proven tough, handling pressure and delivering consistent performance. This reliability makes it a standout compared to traditional catalysts like iridium or ruthenium, which cost more and often supply chain headaches. Years spent in shared labs taught me to appreciate materials that keep going without daily tweaks. For green hydrogen production—a field striving to lower costs—switching to stable, earth-abundant materials means more than a few pennies saved. Over time, it drives the price of clean fuel closer to what people pay for gasoline or natural gas.

Cobalt borate’s action in water splitting places it at the crossroads of chemistry, engineering, and global markets. Still, this compound doesn’t always get used in pure form. Scientists layer it onto electrodes or use it in blends, chasing the best blend of power and endurance. Data from recent peer-reviewed studies, like those found in journals such as ACS Energy Letters and Nature Communications, back up cobalt borate’s edge over older catalyst materials. My own experience running electrochemical tests agrees. The numbers look good, but costs and practical scalability leave room for honest talk. Mining cobalt raises ethical and environmental questions. Large projects sometimes source cobalt from regions with poor labor practices or significant environmental fallout. Boron doesn’t challenge supply lines in the same way, but global demand for cobalt still keeps researchers hunting for alternatives.

Industry can’t change overnight. Most projects using cobalt borate remain small, with universities and startups leading the way. Scaling up means solving not only technical challenges but also supply ones. Teams need clean supply chains, reliable materials, and support for recycling spent catalysts. Companies and governments face choices: invest in better mining practices, fund alternatives, or push for better recycling. As someone who’s watched technology move from bench to pilot plant, I’ve seen both victories and setbacks. Cobalt borate offers real promise, but it won’t drive energy transformation alone. Collaboration—across countries and across sectors—matters most. Only by sharing knowledge, improving sourcing, and funding real-world deployments will the true impact of cobalt borate come to life.

Cobalt sits on my shelf in a tiny dark bottle, reminder of college days spent hunched over glassware and powders. Cobalt borate showed up only in small quantities, but its bright presence in chemical stains and catalysts hinted at something much larger. Hidden behind that bright color lies a set of health risks often glossed over in lab manuals or glossed up in product listings.

It's tempting to focus on cobalt borate's utility—batteries, ceramics, pigments, neat little glass projects. Yet, ignoring safety simply misses the bigger picture. The trouble starts when you look at the dust. Many people who work with fine powders—artists, scientists, hobbyists—don’t always realize how easy inhalation can become. Airborne cobalt compounds find their way into lungs, not by dramatic accident, but by the slow shuffle of pouring, brushing, mixing.

Cobalt has a reputation. Inhaled cobalt compounds, including cobalt borate, irritate the respiratory system and can trigger asthma or fibrosis after repeated exposure. For some, that means wheezing and coughing that just won’t fade. Toxicologists also point to cobalt’s suspected role as a carcinogen. The International Agency for Research on Cancer classifies cobalt compounds as possibly carcinogenic to humans. Sprinkle in the fact that borate compounds can mess with reproductive health, and the mixture packs a punch that few expect from such color and calm at first sight.

Traditional hazard labels back this up. There are warnings for skin and eye irritation, potential lung issues, and environmental risks too. Cobalt borate doesn’t just stay where you put it: powder washes into drains or spills in workshops, moving into water systems. There, cobalt accumulates in plants and animals. Small doses may not transform an environment overnight, but as dust and waste build up, the story changes.

Few people regularly handle cobalt borate at home, but for those in laboratories, ceramics studios, or factories, the risk grows quickly if basic precautions slip. Disposable gloves, dust masks, goggles and proper ventilation make a big difference; I learned this after a coughing fit drove me from a poorly ventilated art studio. Permanent respiratory damage isn’t a story anyone wants to be part of, especially for a material that finds its way into beautiful blue glazes and shiny cathodes.

Practical risk management doesn't require a laboratory degree. Simple steps—storing materials away from children, never eating or drinking around powders, cleaning with a wet mop instead of sweeping—go a long way. It’s the kind of workplace wisdom passed from an old-timer’s mouth rather than a manual: “Don’t let it settle in your lungs or your sink.”

The story of cobalt borate, then, isn’t just one of chemistry. It’s about responsibility, about knowing what happens before and after a powder leaves the jar. Regulators call for labeling, environmental rules, and worker protections, but change often starts at the bench, in the habit of double-checking your gloves or swapping a brush for a vacuum.

No one needs to fear every colored powder or workplace chemical, but a little respect for the hidden hazards—grounded in experience and a dose of scientific fact—makes all the difference between a safe experiment and an unnecessary risk.

Cobalt borate, a powder known for its deep blue color, pops up in laboratories, ceramics studios, and battery development. The stuff poses health risks if handled carelessly. It’s toxic, irritates skin and the respiratory system, and can contaminate environments if spilled. Regular storage mistakes open the door to emergencies nobody wants: chemical burns, heavy metal exposure, or expensive cleanup.

Anyone working with chemical powders can tell you—the difference between a safe space and a hazard zone boils down to daily habits. For cobalt borate, it pays to start with the right container. Tough, airtight plastic or glass jars keep the contents dry and prevent any escape into the air. Screw caps beat snap lids here; nobody wants a cloud of powder greeting them when opening a cabinet.

Humidity creates headaches with chemicals. Moisture in the air can cause clumping, break down purity, or even create new hazards through unwanted reactions. Store cobalt borate in a dry, low-humidity location. Some labs run dehumidifiers, but at home or in small studios, I’ve done fine with silica gel packs tucked alongside the jars. They soak up stray moisture and offer cheap insurance.

Don’t rely on memory or faded stickers. Permanent labels, legible and dated, make a real difference. I mark every jar with the full name, hazard warnings, and the date filled. This habit helps visitors, inspectors, and future-me remember—nobody has perfect recall months later. Clear labels also lower the risk of accidental mix-ups, especially since several blue pigments look nearly identical at first glance.

Shelves that sit at eye level, in a solid ventilated cupboard, offer better protection than a packed drawer or cluttered open shelf. Secure cabinets, preferably locked, keep children and pets away. I worked in a ceramics studio where a jar fell from a high open shelf and sent powder everywhere—an hour spent in cleanup beats the quick fix of proper shelving from the start.

Ventilation plays a major role. Dust from cobalt borate harms lungs, even in small doses over time. Good air movement, extraction fans, and the habit of opening containers under fume hoods or near open windows cut exposure risks. I wear a certified dust mask, not a simple cloth mask, to avoid breathing in fine particles while scooping.

No one thinks trouble will strike until it does. Spills and exposure still happen, so a clear set of emergency instructions near the storage spot prevents panic. Gloves and goggles should sit within arm’s reach. Spill kits—complete with damp cloths, waste bags, and easy directions for disposal—turn a scramble into a quick, safe fix. Workers and hobbyists need simple training: how to seal a spill, how to handle accidental contact, and how to tell if someone’s breathing dust.

Safe storage comes down to respect for chemical risks and a personal habit of order. Organizations like the Occupational Safety and Health Administration offer public guides for handling hazardous powders; local waste authorities often take hazardous chemicals for safe disposal. There’s no trophy for taking shortcuts with toxic compounds. A measured, practical setup wins every time—protecting health, project success, and peace of mind.

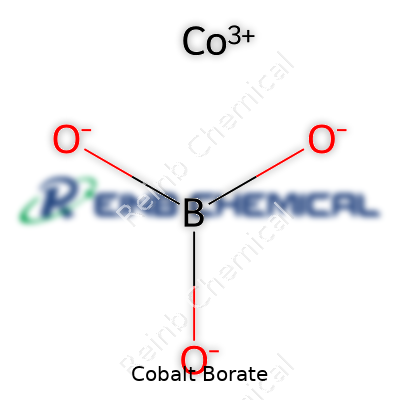

Chemical formulas don’t get much limelight, but they shape the workbench for anyone dealing with materials research and industrial chemistry. Cobalt borate may seem like a footnote compared to big-league compounds, yet its formula, Co3(BO3)2, carries practical weight. I spent time in labs where accuracy mattered more than ambition—drop a single number in a formula, and you jeopardize the project.

Cobalt borate comes together with three cobalt atoms for every two borate units. Easy to scribble, harder to synthesize. Each time we ran tests using Co3(BO3)2, we checked our compounds twice. Why? Impurities or calculation slip-ups mean wasted batches or skewed data. A correct chemical formula turns a jumbled mixture into a focused tool, especially in energy storage tech and pigment production.

One reason cobalt borate sees respect: it works as a catalyst in water splitting. Electrochemistry labs testing new battery ideas run cycles on Co3(BO3)2 because the material supports oxygen evolution reactions. Published studies from the past five years back this up, with researchers showing improved current densities and stability from cobalt borate-based electrodes. I lost count of the number of times colleagues referenced the precise structure when troubleshooting electrode failures. Accurate formulas serve as the bedrock—nobody wants to redesign a project because their base material was wrong on paper.

Every material comes with baggage. Cobalt, for example, enters headlines for tough reasons: tight global supplies and tough mining conditions. Sourcing cobalt borate isn’t just a chemistry concern. Companies and researchers buying Co3(BO3)2 from the wrong supplier risk not only bad data but also ethical headaches. Working on projects involving cobalt borate, our team checked supplier certifications and kept an eye on independent lab tests of purchased stock.

Chemistry isn’t just for researchers and industrial teams—students and hobbyists should get the basics before mixing anything in a beaker. Years ago, my first brush with cobalt borate came through a high school science kit. The kit glossed over chemical names, but the formula got drilled into us. Later, that foundation made college lab work less of a guessing game. Without clear, reliable information about formulas and handling, newcomers face increased risks. Transparency matters. I remember colleagues sharing not only procedures but real data sheets and verified safety information. That culture kept accidents rare.

Keeping Co3(BO3)2 in the conversation requires more than catalog entries. Publicly available research, teacher guides, and supplier transparency help steer new users in the right direction. For those working in labs, the recommendation stays simple: double-check the formula and don’t skimp on safety. For industry buyers, reliable sourcing backed by third-party validation trims risk and reduces long-term headaches. Open communication helps everyone keep their projects on track—and protects folks from learning safety lessons the hard way.

People often see chemistry as a closed world of equations and obscure names, but it doesn’t take long—playing in a high school lab, testing colors on filter paper, or even working in industrial settings—to realize that each substance brings its own quirks. Take cobalt borate, for example. This compound doesn’t make headlines, but its solubility can shape research directions and everyday industry jobs. Whenever a chemist considers using a new material, a crucial question pops up: “What happens if I add this to water?”

Solubility isn’t just some textbook technicality. It determines waste handling, impacts the environment, and even shapes production costs. Cobalt borate (often written as Co3(BO3)2) simply doesn’t dissolve in water under normal conditions. That’s based on both old-school lab texts and current material safety data sheets. So if you’re hoping to stir it into water and see it vanish, you’ll be staring at a cloudy, stubborn suspension. The compound stays put at the bottom, refusing to play along with common solvents like water.

Let’s break this down a bit. Cobalt borate holds together with solid ionic bonds—cobalt ions hugged tightly to borate groups. Water likes to pull ions apart, but the bond in this compound resists. Lab tests confirm its insolubility: even in hot water, cobalt borate won’t budge. This trait helps in battery materials and pigments because it keeps the compound stable over time, even if humidity gets high. I’ve seen old ceramic glazes survive decades, thanks in part to this sort of robust chemistry.

In the factory, solubility impacts cleanup and disposal. Solutions can wind up down the drain more easily (after neutralizing), but insoluble solids like cobalt borate call for extra care. There are safety rules, since any cobalt compound carries health concerns—chronic exposure may risk lung and heart problems. So, the fact that cobalt borate resists dissolving gives protection against sudden contamination but also means extra cost and work in disposal. Environmental rules keep tightening. If this gets tossed with careless waste, cobalt stays locked in solid form, but it’s still a long-term pollutant, building up in soils or sediments over years.

If research demands a water-based cobalt source, chemists go with cobalt chloride or cobalt nitrate instead; both dissolve quickly. For pigment makers or battery designers wanting water resistance, cobalt borate is the right call. Some researchers are even exploring borates for next-gen batteries, since the lack of solubility adds safety and cycle stability. As for factories, the solution isn’t tricky chemistry, but smart waste management: using proper landfills, treating effluent water, and finding ways to recover cobalt, since it’s a metal with growing demand worldwide.

Cobalt borate earns its spot as an insoluble material—not just a chemical fact, but a choice that influences jobs, ecosystems, and future technologies. Whether working behind a bench or managing a plant, knowing what happens when you add a powder to water makes all the difference.

| Names | |

| Preferred IUPAC name | Cobalt(2+) dioxido(dioxo)borate(2−) |

| Other names |

Boric acid cobalt(2+) salt Cobalt diborate Cobalt(II) borate Cobaltous borate |

| Pronunciation | /ˈkoʊ.bɔlt ˈbɔː.reɪt/ |

| Identifiers | |

| CAS Number | 12008-64-1 |

| Beilstein Reference | 1721846 |

| ChEBI | CHEBI:60177 |

| ChEMBL | CHEMBL1231878 |

| ChemSpider | 20369945 |

| DrugBank | DB11134 |

| ECHA InfoCard | 07ca2baf-28e9-4518-93b9-5f93f84259ea |

| EC Number | 235-572-6 |

| Gmelin Reference | 105846 |

| KEGG | C17661 |

| MeSH | D000077238 |

| PubChem CID | 16212294 |

| RTECS number | GL7875000 |

| UNII | 8J27G2UO1C |

| UN number | UN3077 |

| Properties | |

| Chemical formula | CoBO₂ |

| Molar mass | 122.73 g/mol |

| Appearance | Blue powder |

| Odor | Odorless |

| Density | 2.82 g/cm³ |

| Solubility in water | Insoluble |

| log P | -0.62 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 16.2 |

| Basicity (pKb) | 11.4 |

| Magnetic susceptibility (χ) | +222×10⁻⁶ |

| Refractive index (nD) | nD ~1.83 |

| Dipole moment | 2.32 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 71.0 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | -732 kJ/mol |

| Pharmacology | |

| ATC code | V09DX04 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and serious eye irritation, may cause respiratory irritation, may damage fertility or the unborn child. |

| GHS labelling | GHS02, GHS07, GHS08 |

| Pictograms | GHS07,GHS09 |

| Signal word | Danger |

| Hazard statements | H302+H332, H317, H319, H334, H335, H341, H350, H360, H372, H410 |

| Precautionary statements | Precautionary statements for Cobalt Borate: "P201, P202, P261, P264, P270, P272, P273, P280, P302+P352, P304+P340, P308+P313, P312, P314, P321, P362+P364, P405, P501 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 0, Instability: 0, Special: - |

| Lethal dose or concentration | LD50 oral rat 5,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >2000 mg/kg (oral, rat) |

| NIOSH | B0283 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Cobalt Borate: "0.1 mg/m3 (as Co), OSHA PEL |

| REL (Recommended) | 0.01 |

| IDLH (Immediate danger) | IDLH: Not established |

| Related compounds | |

| Related compounds |

Cobalt(II) oxide Cobalt(II) carbonate Cobalt(II) hydroxide Nickel borate |