In the early days of organophosphorus chemistry, triphenyl phosphite emerged as one of those materials that quickly caught the attention of researchers working on both synthetic challenges and practical applications. Chemists in the 1920s and 1930s began experimenting with phosphite esters, and triphenyl phosphite soon earned a place in this new class of compounds. The timeline of its development serves as a testament to the growing curiosity around phosphorus chemistry, driven by the discovery of versatile agents for organic synthesis and industrial production. Researchers realized this compound could unlock new pathways in both laboratory methods and manufacturing, changing how chemists thought about phosphorus-based reagents. In the decades since, triphenyl phosphite has established its utility, spurred advances in synthetic chemistry, and become an essential component in everything from polymer stabilizers to specialized ligands in catalytic cycles.

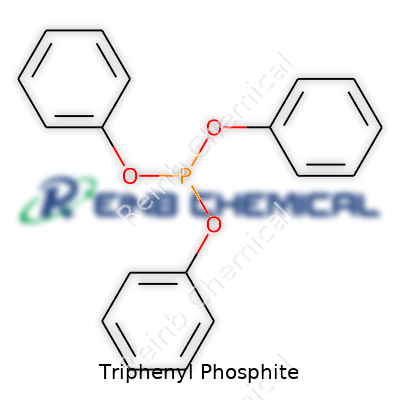

Triphenyl phosphite, often recognized by its chemical formula C18H15O3P, contains three phenyl groups attached to a phosphorus atom through oxygen bridges. In a transparent liquid form at room temperature, it holds a sweet yet faintly aromatic smell. Manufacturers and research labs depend on its consistent quality for a wide range of reactions. Bulk quantities often appear in amber glass containers or drums, with labels highlighting its capacity to protect polymers against oxidative degradation, its reliability as a solvent stabilizer, and its well-known function as a reagent in preparing phosphorus-containing compounds. Its shelf stability and reactivity attract chemists searching for both reliability and versatility on the workbench.

Triphenyl phosphite looks clear or pale yellow and remains a liquid at ordinary temperatures, thanks to its melting point near 22°C and boiling point hovering around 360°C. A density close to 1.185 g/cm³ enables straightforward handling compared to heavier phosphorus chemicals. This compound dissolves well in organic solvents—toluene, benzene, ethanol—yet shows little solubility in water. It does not ignite rapidly, with a flash point nearing 210°C, and typically stays stable in well-sealed containers outside direct sunlight and sources of heat. Chemically, triphenyl phosphite displays notable activity as a Lewis base, coordinating readily with a spectrum of transition metals, which makes it valuable in catalysis. Its molecular structure and reactive lone pairs push chemists to explore new ligands, coupling agents, and synthetic pathways.

Manufacturers report minimum assay levels for triphenyl phosphite at or above 99%, ensuring reliable quality each time. Key specs appear in safety data sheets and product labels: appearance (clear or faint yellow liquid), molecular weight (310.28 g/mol), flash point (typically just above 210°C), refractive index (around 1.585 at 20°C), and water content (usually below 0.05%). Labels frequently display batch number, expiration, and recommended storage conditions—cool, dry, and shielded from light or incompatible chemicals. Labels reflect key handling warnings, emphasizing the need for eye and skin protection given its mild irritant qualities.

Chemists commonly prepare triphenyl phosphite through the reaction of phosphorus trichloride with phenol in a suitable solvent. Careful addition of phenol to phosphorus trichloride under controlled temperatures, usually in the presence of a base like pyridine, leads to substitution of chlorine atoms with phenoxy groups. Stirring continues for several hours while hydrochloric acid byproduct is liberated. After the reaction, purification follows through distillation under reduced pressure, yielding a high-purity, nearly colorless product. Researchers in small labs and industrial facilities both value this method for its practicality and scalability; with proper controls and experience, technicians can consistently reach product purity targets.

In everyday work, triphenyl phosphite serves as a versatile participant in organic synthesis. It functions as a ligand in homogeneous catalysis, forming stable complexes with palladium, nickel, and other transition metals for cross-coupling reactions and hydrogenations. In the presence of alkyl halides, it reacts to form triphenylphosphonium salts—key intermediates for Wittig reactions. Under strong oxidative conditions, triphenyl phosphite converts to triphenyl phosphate, a compound often used in flame retarding applications. Chemists have exploited its reactivity for selective phosphorylation, esterification, and as a reducing agent, often favoring it due to its manageable reactivity and ease of blending with other organic reagents. This adaptability keeps triphenyl phosphite at the core of new synthetic strategies.

In different catalogs and scientific references, triphenyl phosphite may also appear as Phosphorous acid, triphenyl ester; Triphenoxyphosphine; and Trifenylphosphit. These names reflect the compound’s structure and point to its foundation in phenol and phosphorus chemistry. International suppliers use standardized names to ensure chemists and procurement teams speak the same language when ordering or specifying reagents, removing ambiguity from critical production and research processes.

Work with triphenyl phosphite demands basic but serious precautions. Though not acutely toxic, it behaves as an irritant for eyes, skin, and the respiratory tract. Facilities keep operations under fume hoods during weighing, mixing, or transfers, providing gloves, goggles, lab coats, and stringent cleanup protocols to prevent contact. Storage requires cool, dry, and well-ventilated environments, well away from acids or strong oxidizers that might trigger unwanted reactions. Emergency procedures and material safety data guide teams so everyone knows the right steps for spills or accidental contact. Industrial sites and academic labs uphold these standards not only to comply with law but also to promote a healthy workplace culture and avoid costly, dangerous accidents that can arise from complacency.

Industry relies on triphenyl phosphite as a stabilizer in plastics and polymers, especially for polyvinyl chloride (PVC) and related products. I have worked with extrusion lines whose output—cables, conduits, and sheets—depend on added phosphorus esters like triphenyl phosphite to hold up against heat and oxidation during both manufacture and long-term use. Paint and coatings sectors use it for similar reasons, slowing yellowing and deterioration under exposure to sunlight or harsh conditions. Chemists favor it in fine chemical synthesis, particularly as a phosphorylating or reducing agent for complex organic reactions. Research labs scrutinize its performance as a ligand or additive in catalytic systems, constantly seeking sharper results in pharma and agrochemical synthesis.

Scientists and R&D specialists keep exploring new uses for triphenyl phosphite, particularly in catalysis and materials science. Coordination chemistry advancements depend on novel ligand architectures, with triphenyl phosphite offering a blend of electron-donating properties and manageable sterics. In electronics manufacturing, its potential to scavenge peroxides or stabilize polymers draws interest in next-generation insulation and encapsulation materials. Researchers have experimented with structural modifications—adding alternative substituents or incorporating the phosphite core in larger molecular assemblies—to fine-tune reactivity for specialty chemicals. In these settings, deeper understanding means teams can unlock new synthetic routes, lower waste, and push efficiency higher.

Toxicological studies of triphenyl phosphite document it as a low-to-moderate hazard under typical laboratory and industrial exposures, but not harmless. Ingestion or inhalation above established thresholds may cause discomfort or mild poisoning, usually reversible once exposure stops. The compound lacks evidence for significant carcinogenicity or long-term bioaccumulative risk at workplace concentrations, though chronic exposure can cause irritation or mild organ disturbance if workers neglect personal protective equipment. Animal studies have not turned up acute effects at low doses, but prudent handling and respect for potential hazards dominate official guidance. Regulatory agencies include it on lists for chemical inventory management and require proper documentation for safe carriage, storage, and disposal.

Looking forward, triphenyl phosphite will maintain strong relevance both in established applications and in exploring sustainable, efficient chemical transformations. With ongoing demand for stable, high-performance plastics and coatings, engineers and scientists will refine additive packages using this and similar phosphite esters. In catalysis and advanced materials, research effort tracks towards designing ever more selective and active systems based on phosphorus ligands, and triphenyl phosphite serves as a reliable starting point for these investigations. Regulatory changes and shifting consumer priorities may drive industry to examine environmental fate and greener alternatives, but for now, pragmatic chemistry and engineering continues to put this versatile compound at the intersection of invention, manufacturing, and global supply networks.

People rarely think about triphenyl phosphite or know what it does, but this chemical shows up in places many wouldn’t expect. If you’ve ever opened a pack of cling wrap, handled a plastic bottle, or unwrapped wires from a new gadget, there’s a good chance you’ve been close to it. My own work in a plastics lab years back gave me a front-row seat to how manufacturers mix chemicals hoping to get their blends just right. Triphenyl phosphite became familiar fast, showing up on materials lists almost as often as polyethylene or PVC.

Plastic looks simple, but it can fall apart if it’s exposed to light, heat, or air for too long. There’s a chemistry war happening behind the scenes—heat breaks bonds, light creates free radicals, and over time, plastics can yellow, crack, or lose their shape. Triphenyl phosphite acts as a stabilizer in those plastics. It gets added during production to help protect plastics from breaking down. The key reason this works: it reacts with compounds that would otherwise damage the plastic. Instead of letting the process spiral, triphenyl phosphite grabs those harmful molecules, making the product last longer. Anyone who’s ever pulled out an old piece of plasticware that still looks clear and flexible instead of yellowed or brittle is seeing the benefit.

Manufacturers use triphenyl phosphite for more than just preventing plastic damage. In the world of lubricants and hydraulic oils—which power cars, planes, and big machines—triphenyl phosphite serves as an antioxidant. That means it slows down reactions caused by heat and oxygen, cutting down on sludge and helping machinery run smoother for longer. This matters in places like factory floors or auto workshops, where downtime costs real money. I remember watching colleagues try to stretch the life of machine oils, and surprisingly, a little tweak in additive chemistry, including triphenyl phosphite, could mean the difference between weeks and months of uninterrupted runs.

The fact that triphenyl phosphite finds its way into food packaging naturally makes anyone think about safety. Health authorities, including the U.S. Food and Drug Administration, keep a close watch. It’s only approved in strict limits, after manufacturers prove they’re not overusing it. Labs check for how much can leach out of packaging into food, and safety studies look for any evidence of harm. Together with rules and lab data, triphenyl phosphite stays off the public radar as long as manufacturers keep within these safety boundaries.

One ongoing issue: production workers around this chemical need solid protection, since exposure in high doses can irritate skin and eyes. Responsible plant managers put training and safety gear above all else. That’s not just a legal thing—it makes sense, because keeping people healthy cuts turnover and keeps morale steady. The push for greener additives is real, and some companies are already exploring plant-based stabilizers, hoping to cut down reliance on synthetic chemicals.

Innovation keeps moving. Polymer chemists are studying ways to tune up the performance of plastics through alternative stabilizers, some drawing on discoveries around triphenyl phosphite’s reactivity but using materials that break down faster in the environment. I’ve watched university labs run experiments modeling years of sunlight and heat, reporting results on which additives keep plastics strong with less environmental baggage. As pressure rises on industries to go green, the hunt for better stabilizers will matter even more. Triphenyl phosphite helps lift everyday products, but its long run in the spotlight depends on how well chemists and manufacturers can balance performance with safety and responsibility.

Triphenyl phosphite pops up in more places than people think. This chemical plays a role as a stabilizer in plastics manufacturing, a flame retardant in some materials, and sometimes even as an antioxidant in rubber production. Plenty of workers in industrial settings come across it, sometimes without realizing what’s in the drum beside their line. Since it’s colorless and carries a slight but sharp odor, it doesn’t scream “hazard” right away. Yet, it pays to be cautious around substances that fly under the radar in day-to-day use.

Spending time around triphenyl phosphite means exposure could hit you through the skin, lungs, or mouth. The direct effects draw from its chemical nature. If this liquid gets on your hands, irritation kicks in fast – redness, itching, even burns in severe cases. Eye contact leads to stinging and possible long-term vision problems if the splash stays untreated. Breathing in the vapors, especially if heating or mishandling happens in close spaces, can trigger headaches, coughing, throat soreness, and in worse cases, trouble breathing. Anyone who has spent hours troubleshooting an overheating pump in a factory knows the feeling of wanting fresh air after dealing with chemical fumes.

Studies with lab animals point to toxicity with regular exposure, targeting organs like the liver and causing other systemic issues. Data from the European Chemicals Agency highlights that repeated, high-level exposure to triphenyl phosphite damaged rodents’ livers, kidneys, and lungs. On top of that, safety data sheets show it could cause allergic skin reactions, which match what some seasoned workers have reported after frequent or prolonged handling.

For most folks, risk mostly lands on workers in chemical, synthetic fiber, or plastic facilities. Mistakes in ventilation systems, spills, or poorly labeled drums lead to serious accidents. I remember a conversation with an industrial hygiene specialist who tracked a sudden rash of headaches among staff, later pinned on an overlooked container leaking triphenyl phosphite vapors.

Outside of factory walls, everyday encounters remain rare. That said, chemicals used to make or treat plastics don’t vanish. Down the line, traces could seep into groundwater or stick around in dust on old equipment, raising questions about long-term exposure and environmental build-up that nobody has answered yet. Once plastics break down, so do additives like triphenyl phosphite, bringing a fresh round of unknowns.

Simple steps matter. Anyone using triphenyl phosphite directly ought to suit up with protective gloves, goggles, and proper respiratory protection, especially in areas with poor airflow. Routine monitoring with air sensors and clear labeling on all containers gives teams the heads-up they need. I’ve seen workplaces where weekly training on chemical hazards kept incidents low, just by making hazards feel real, not abstract.

Government agencies set exposure limits, but these sometimes lag behind new research. Employers can beat the bare minimum by investing in better fume hoods, spill response kits, and regular health checkups for teams most in contact with these substances.

Calling for improved transparency from manufacturers can help users and communities understand what they’re dealing with. Researchers could do more to pin down what low, chronic exposure looks like in real people and not just lab animals. Safer alternatives already exist for some uses, especially as technology keeps moving. Openness, clear labeling, and smart safety habits remain the best shields for now, facing the unknowns of these quiet but potent chemicals.

Ask a chemist about triphenyl phosphite, and chances are the answer comes fast: C18H15O3P. This isn’t just a formula on paper—it stands for a versatile compound that shows up in labs from New Jersey to New Delhi. Imagine fifteen hydrogen atoms and eighteen carbons, all joined by three oxygen atoms and capped with a single atom of phosphorus. That’s the skeleton of this molecule. The three benzene rings linked to phosphorus give it more than just a complicated name. This structure influences how it behaves in science and in industry.

Triphenyl phosphite often slides under the radar, but it plays a quiet role behind plenty of materials we rely on. Its unique makeup makes it useful as a stabilizer in plastics, a ligand in catalysis, and a reagent in organic synthesis. In simpler terms, it helps chemists connect molecules or keep materials from breaking down too soon. As a researcher, I’ve seen it used to boost the performance of flexible PVC, adding longer life to things like car interiors and hospital tubing. Making plastics last matters—think of the costs saved by fewer replacements and the reduction of waste headed to landfills.

Its presence in chemical reactions reminds us that structure can change everything. The way triphenyl phosphite holds its three phenyl groups around phosphorus allows it to act as a “ligand”—kind of like a molecular handshake for metals in catalytic reactions. These handshakes impact processes from medicine production to cleaner fuels. Miss that structure, and efficiency drops. Its role as a reagent for introducing phosphorus into new compounds opens up doors for everything from flame retardants to pharmaceuticals. The backbone remains the same, but chemists can tweak the rest to suit what’s needed.

Experience in the lab teaches respect for chemicals like triphenyl phosphite. Despite its benefits, it brings risks—especially to skin, eyes, and lungs. Anyone handling it needs solid training, gloves, goggles, and fume hood access. Old habits (like ignoring Safety Data Sheets) can get people hurt. Evidence from industrial settings points to rare but real concerns if the compound is mishandled. Data from the U.S. National Institutes of Health puts its toxicity at a moderate level but calls for vigilance because burns and breathing issues can happen in poorly ventilated spaces.

Managing these risks means more than regulation. It means ongoing training and investment in equipment. Facilities benefit from spill control plans and updated chemical management systems. I’ve seen progress when companies create a culture of safety, not just compliance. That’s where awareness programs, worker feedback, and rapid accident reporting save lives.

There’s no reason to stop at tradition. Scientists all over the world keep searching for alternatives to triphenyl phosphite in applications where safer, greener options might work just as well. Some teams look to plant-based stabilizers, others develop new ligands using less hazardous elements. Still, the familiar formula C18H15O3P keeps turning up because of its proven reliability—at least for now. The chemical industry has a responsibility to push for more transparent supply chains and better waste handling, so workers and ecosystems aren’t put at unnecessary risk.

Triphenyl phosphite may look like just another line in a chemistry textbook, but it touches much more than a page. That concise formula, C18H15O3P, hides a story shaped by lab results, safety lessons, and ongoing innovation. Progress happens when we learn, adapt, and balance the benefits with the real-world risks that never quite fit in a bottle or on a label.

In every lab I’ve worked in, someone always asks where to put a new bottle of chemicals. Triphenyl phosphite looks harmless enough, but it behaves differently if you don’t treat it with respect. I’ve seen a shipment arrive on a humid afternoon, left in a storeroom without much thought. By the next week, the color had started to turn. Nobody bothers to read the safety sheets until a problem shows up on the bench.

Triphenyl phosphite doesn’t shout “danger,” but its chemistry makes it demanding. Exposure to light and air kicks off slow breakdown. Moisture loves to creep in where it isn’t welcome, turning this compound cloudy and useless. The result is wasted money, unreliable test results, and, once in a while, a mess that’s tricky to clean up.

This chemical finds its way into plasticizers and antioxidants for plastics. That means keeping it pure matters not just for research but for industries where quality translates directly to safety. I’ve had engineers tell me a contaminated batch can throw off a production run, costing companies time and inviting unwanted scrutiny.

The best way to sidestep all these headaches is straight from the people who handle chemicals every day. They lock triphenyl phosphite in air-tight containers made of glass or steel. Someone on the team always checks that the cap sits tight after each use. Forgetting this leads to the telltale smell and sticky residue. To really get it right, people add a desiccant packet—those little moisture-absorbing packs go a long way, especially in humid climates.

Darkness is more than a preference here. Bright lights speed up unwanted changes, so the smart move is to keep the bottle in a dark cabinet or drawer. Some labs set up special flammable storage cabinets since this chemical doesn’t mix well with fire hazards. Nobody wants to see the fire department visit because a simple rule got ignored.

Trusting people to follow every label helps, although I’ve seen plenty of shortcuts. Training makes a big difference—once people see what happens after sloppy handling, most take the rules to heart. I’ve watched seasoned lab techs share stories with new hires about ruined batches or persistent odors lingering for days. Real-world consequences get people’s attention in a way warning labels never do.

Records make everyone’s life easier. Recording the date a container opens gives a reminder to replace old stock before it goes south. Sharing this habit across work shifts avoids surprises for the next person. Good communication and labeling give every chemical a longer, safer shelf life.

I’ve worked in places with tight budgets and old equipment. Even there, following these practices made a clear difference. Fact sheets from trusted sources like OSHA and chemical suppliers offer rock-solid advice, and I see more labs tap into those resources to train staff. A little up-front effort pays off by controlling risks and costs. It boils down to a simple truth: treating triphenyl phosphite with care lets everyone get on with the real work, safe and worry-free.

Triphenyl phosphite gets used in labs and some industries because it works as a stabilizer and an antioxidant. This chemical brings along hazards most folks outside a lab might not think about. Many accidents happen when people underestimate what a liquid can do, especially one almost clear and faint-smelling like this. Everything looks calm—until someone ends up with a burn or, worse, an asthma attack.

Just using a fume hood and calling it good never cuts it. Skin contact leads to irritation fast. Splashes have ruined plenty of afternoons—my own included—thanks to skipping gloves or rolling up sleeves. Nitrile gloves, sturdy goggles, and a lab coat don’t just show off professionalism, they put a barrier between your skin and something you can’t just wash away with water. I’ve seen coworkers argue that “just this once” without gloves isn’t a big deal, then days later deal with red, itchy patches hard to explain away. Eye protection means goggles, not glasses, because vapor and tiny splashes travel farther than you’d think.

The fumes from triphenyl phosphite carry real weight. Sneaky vapors drift into the air, and standard air conditioning won’t clear them out. Anyone working around it knows a fume hood isn’t optional—good ventilation keeps those vapors from hitting your lungs. I once had a lab mate ignore the fume hood rule for what she thought was a “quick” pipetting step. She walked away coughing for hours, scaring herself and everyone nearby. Safety data nails this point home: repeated exposure could spark breathing problems in people with asthma or cause headaches strong enough to knock out productivity.

Spills cause chaos, especially when handled out of panic. Keeping absorbent material handy stops spread. Quick action with the right spill kit—never paper towels or casual rags—makes a difference. Containers play their part too: sturdy glass with a tight cap. Triphenyl phosphite doesn’t get along with air or water, so leaks or loosely-closed jars create risk nobody wants. I remember one poorly-stored bottle corroded its cap, leaking enough to fill the storage room with awful fumes. No lab alarm was needed to clear that out—everyone ran for fresh air on instinct. Safety means checking bottles every week for signs of wear and not pushing luck with old stock.

Pouring unused triphenyl phosphite down the drain turns a bad day into an environmental problem. Waste needs a specialty disposal container, labeled and sealed away from incompatible chemicals. Labs that rush cleanup for the sake of speed invite fines and health trouble. There’s real peace of mind in knowing that the chemicals you use today won’t poison someone else’s water tomorrow.

No manual covers everything—the lessons that stick come from real drills and walk-throughs. Even seasoned chemists benefit from reminders. The most useful safety briefings break out gloves, spill kits, and encourage open talk about “near-miss” accidents so nobody gets caught off guard. Over time, good habits add up to safe floors and clear air. Triphenyl phosphite only hurts when it’s not taken seriously. Anything less turns a tool into a threat.

| Names | |

| Preferred IUPAC name | Triphenyl phosphite |

| Other names |

Phosphorous acid triphenyl ester Triphenoxyphosphine TPP Triphenyl phosphonate |

| Pronunciation | /traɪˈfɛ.nɪl ˈfɒs.faɪt/ |

| Identifiers | |

| CAS Number | 101-02-0 |

| Beilstein Reference | 80363 |

| ChEBI | CHEBI:132941 |

| ChEMBL | CHEMBL504264 |

| ChemSpider | 10199 |

| DrugBank | DB14137 |

| ECHA InfoCard | ECHA InfoCard: 100.007.815 |

| EC Number | 200-928-8 |

| Gmelin Reference | 59729 |

| KEGG | C14687 |

| MeSH | D014277 |

| PubChem CID | 66239 |

| RTECS number | WX8575000 |

| UNII | H28F7BQ5Z5 |

| UN number | UN2325 |

| Properties | |

| Chemical formula | C18H15O3P |

| Molar mass | 310.28 g/mol |

| Appearance | Clear, colorless liquid |

| Odor | Odorless |

| Density | 1.183 g/cm³ |

| Solubility in water | Insoluble |

| log P | 5.6 |

| Vapor pressure | <0.0001 mmHg (25 °C) |

| Acidity (pKa) | 7.2 |

| Basicity (pKb) | 6.5 |

| Magnetic susceptibility (χ) | -73×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.585 |

| Viscosity | 150 mPa·s (20 °C) |

| Dipole moment | 3.13 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 370.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -173.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5811 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V06DB |

| Hazards | |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H315, H319, H411 |

| Precautionary statements | P280, P273, P305+P351+P338, P501 |

| NFPA 704 (fire diamond) | 1-1-0-0 |

| Flash point | Flash point: 220 °C |

| Autoignition temperature | 480 °C |

| Lethal dose or concentration | LDLo oral rat 1800 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 2700 mg/kg |

| NIOSH | TF0350000 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 3 mg/m³ |

| IDLH (Immediate danger) | 200 mg/m3 |

| Related compounds | |

| Related compounds |

Trimethyl phosphite Triethyl phosphite Trioctylphosphine oxide Triphenylphosphine |